-

Activated Carbon For Air & Gas Treatments

Technology

These series of activated carbon in granular form are made from fruit net shell or coal, activated via high temperature water steam method, under the process of crushing after treatment.Characteristics

These series of activated carbon with large surface area, developed pore structure, high adsorption, high strength, well washable, easy regeneration function.Using Fields

To be used for gas purification of chemical materials, chemical synthesis, the pharmaceutical industry, drink with carbon dioxide gas, hydrogen, nitrogen, chlorine, hydrogen chloride, acetylene, ethylene, inert gas. Used for atomic facilities such as exhaust purification, division and refined. -

Activated Carbon For Water treatment

Technology

These series of activated carbo are made from coal.

The activated carbon processes are accomplished by using one combination of the following steps:

1.) Carbonization: Material with carbon content is pyrolyzed at temperatures in the range of 600–900℃, in absence of oxygen (usually in inert atmosphere with gases like argon or nitrogen).

2.)Activation/ Oxidation: Raw material or carbonised material is exposed to oxidizing atmospheres (carbon monoxide, oxygen, or steam) at temperatures above 250℃, usually in the temperature range of 600–1200 ℃. -

Activated Carbon For Chemical Industry

Technology

These series of activated carbon in powder form are made from sawdust, charcoal or fruit nut shell with good quality and hardness, activated via chemical or high temperature water method, under the after treatment process of scientific formula refined form.Characteristics

These series of activated carbon with large surface area, developed microcellular and mesoporous structure, large volume adsorption, high rapid filtration etc. -

Activated Carbon For Food Industry

Technology

These series of activated carbon in powder and granular form are made from sawdust and fruit nut shell, activated via physical and chemical methods, under the process of crushing, after treatment.Characteristics

These series of activated carbon with developed mesoporous structure, high rapid filtering, large adsorption volume, short filtering time, good hydrophobic property etc. -

-

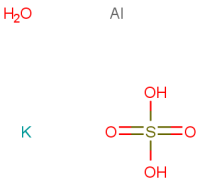

Aluminium Potassium Sulphate

Commodity:Aluminium Potassium Sulphate

CAS#:77784-24-9

Formula:KAl(SO4)2•12H2O

Structural Formula:

Uses:Used for the preparation of aluminum salts, fermentation powder, paint, tanning materials, clarifying agents, mordants, papermaking, waterproofing agents, etc. It was often used for water purification in daily life.

-

Activated Carbon used for Refining Sugar

Technology

Preferentially utilize the low-ash and low-sulfur bituminous coal. Advanced grinding, remodeling briquetting technology. With higher strength and excellent activity.Characteristics

It uses the strict stem activation process to activate. Has a high specific surface and optimized pore size. So that it can absorb color molecules and odor-producing molecules in the solution -

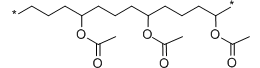

RDP (VAE)

Commodity: Redispersible Polymer Powder (RDP/VAE)

CAS#: 24937-78-8

Molecular formula: C18H30O6X2

Uses: Dispersible in water, it has good saponification resistance and can be mixed with cement, anhydrite, gypsum, hydrated lime, etc., used to manufacture structural adhesives, floor compounds, wall rag compounds, joint mortar, plaster and repair mortar

-

-

Hydroxypropyl Methyl Cellulose (HPMC) Used for Gymsum based plaster

Gypsum based plaster is normally referred to as pre-mixed dry mortar which mainly contains gypsum as a binder. Mixed with water at job-site and used for the finishes on various interior walls – brick, concrete, ALC block etc.

Hydroxy Propyl Methyl Cellulose(HPMC) is an essential additive for optimal performance in each application of gypsum plaster. -

Hydroxypropyl Methyl Cellulose (HPMC) Used for Cement base plaster

Cement based plaster/render is the finishing material that can be applied to any interior or exterior walls.It is applied to interior or exterior walls such as block wall, concrete wall, ALC block wall etc. Either manually (hand plaster) or by spray machines.

A good mortar should have good workability, smear smooth non-stick knife, enough operating time, easy leveling; In today’s mechanized construction, mortar should also have good pumping, to avoid the possibility of mortar layering and pipe blocking. Mortar hardening body should have excellent strength performance and surface appearance, appropriate compressive strength, good durability, no hollow, no cracking.

Our cellulose ether water retention performance to reduce the absorption of water by the hollow substrate, promote the gel material better hydration, in a large area of construction, can greatly reduce the probability of early mortar drying cracking, improve bond strength; Its thickening ability can improve the wetting ability of wet mortar to the base surface.

-

Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives

Tile adhesives is used to attach tiles on concrete or block walls. It comprises cement, sand, limestone, our HPMC and various additives, ready to be mixed with water before use.

HPMC plays an important role in improving water retention, workability, and sag resistance. Especially, Headcel HPMC helps to increase adhesion strength and open time.

Ceramic tile serves as a kind of functional adornment material that is widely used at present, it has different shape and size, unit weight and density also have difference, and how to stick this kind of durable material is the problem that people pays attention to all the time. The appearance of ceramic tile binder to a certain extent to ensure the reliability of the bonding project, the appropriate cellulose ether can ensure the smooth construction of different types of ceramic tile on different bases.

We have wide range products can be used for a variety tile adhesive application to make sure the strength development to achieve excellent bond strength.

We take integrity and win-win as operation principle, and treat every business with strict control and care.